What are Canopy Hoods and How are They Used in Labs?

Jan 9th 2025

Canopy hoods are a vital safety component in laboratory and industrial environments, designed to protect personnel and preserve the integrity of experiments by managing the airflow and containing hazardous fumes, vapors, or particulates. Unlike standard fume hoods, canopy hoods are mounted above equipment and work surfaces, and they are commonly used for local exhaust ventilation (LEV) where chemical processes or reactions take place. In this article, we explore how canopy hoods are constructed, their use in labs, different mounting types, and other important considerations when purchasing them.

What are Canopy Hoods?

A canopy hood is a type of exhaust system typically used to capture contaminants that rise from equipment or processes such as hotplates, reactors, and other laboratory instruments. Canopy hoods are often mounted on ceilings or overhead beams, above the equipment generating fumes or particles. These hoods are engineered to create an efficient airflow that pulls contaminants away from the work area and safely directs them out of the laboratory through ventilation systems.

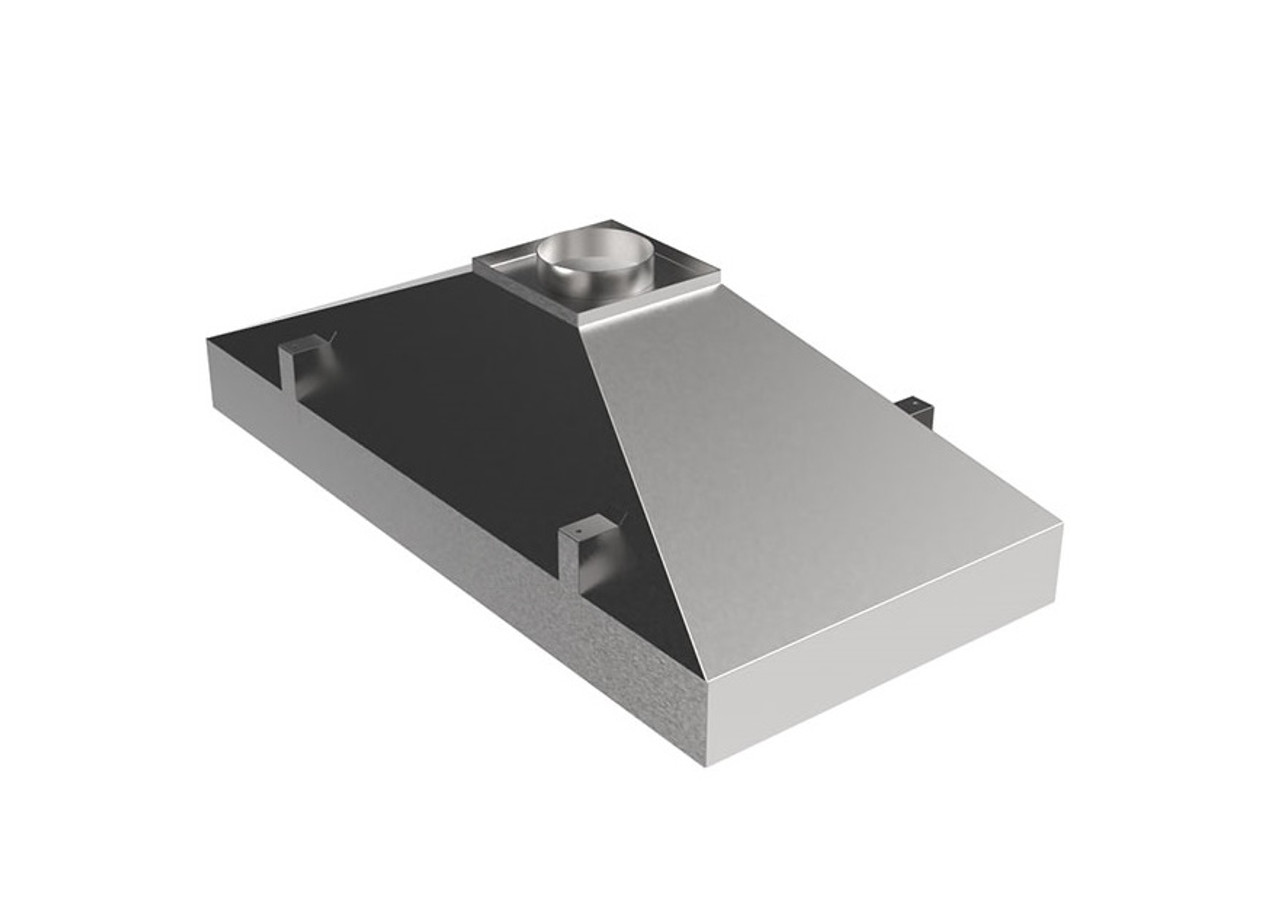

Materials: Canopy hoods are often made from durable materials like stainless steel, polypropylene, or aluminum, depending on the nature of the work and the chemicals involved. Stainless steel canopy hoods are common for their resistance to corrosion and ability to withstand harsh environments. Polypropylene may be used in laboratories dealing with corrosive substances, as it is resistant to a variety of chemicals.

Design: The canopy hood itself consists of a large overhead structure with openings or ducts to allow the contaminants to be drawn up and expelled. The size and shape of the hood depend on the equipment below, ensuring that the airflow can efficiently capture and remove hazardous substances. The air intake is usually located along the edge of the canopy or in a central area to maximize the exhaust capabilities.

Is a Canopy Hood the Same as a Fume Hood?

No.

Canopy hoods and fume hoods are both crucial for maintaining safety in laboratory environments, but they serve different purposes. Canopy hoods are typically mounted above equipment and are designed to capture rising fumes, vapors, and heat from localized sources like hotplates or distillation columns. They create a controlled airflow to direct contaminants toward an exhaust system but do not fully enclose the work area. This makes them ideal for handling smaller amounts of airborne pollutants in situations where full containment is not required. They are often used for tasks where emissions are limited and generated above the equipment.

In contrast, fume hoods are fully enclosed structures designed to contain hazardous chemicals, vapors, and gases. They feature adjustable sashes that provide direct access to the work area while maintaining a barrier between the user and potential contaminants. Fume hoods offer more comprehensive protection, with a controlled airflow that captures and safely exhausts larger volumes of harmful substances. These hoods are essential for more hazardous laboratory processes, such as chemical synthesis or experiments involving volatile substances, providing greater safety for personnel working with dangerous materials.

How Canopy Hoods Are Used in Laboratories

Canopy hoods are primarily used in laboratories where a specific chemical process generates airborne contaminants. These may include fumes, vapors, heat, or particulates that could be hazardous to laboratory personnel. By efficiently removing these contaminants, canopy hoods help maintain a safe working environment.

Some typical uses of canopy hoods include:

- Heat-Generating Equipment: They are commonly placed above heat generating equipment, stirring equipment, or distillation apparatus, where the release of vapors or gases are present.

- Chemical Reactions: In chemistry labs, where chemical reactions may release volatile substances, a canopy hood helps capture these before they reach the breathing zone of lab workers.

- Biological Research: For experiments involving biological agents, canopy hoods can help in safely venting harmful aerosols or vapors generated by biological processes.

Different Mounting Types for Canopy Hoods

Canopy hoods come in various mounting configurations depending on the requirements of the lab and the size of the equipment below. The two primary types of mounting systems for canopy hoods are:

Ceiling-Mounted Canopy Hoods: These hoods are fixed directly to the ceiling of the laboratory, providing an unobstructed working space beneath them. Ceiling-mounted hoods are ideal for larger equipment or for processes that generate a high volume of contaminants. This mounting type offers flexibility, as it can be adjusted to different locations as required for specific lab operations. They are often mounted about laboratory workstations and islands.

Wall-Mounted Canopy Hoods: Wall-mounted hoods are installed directly to the wall. They are often used above perimeter wall work spaces, or above appliances and equipment that are installed in areas where there is power available Installation of these types of canopy hoods are rather easy, given the ability to fasten directly into wall studs, which provides a stable and secure installation.

Features to Consider When Buying a Canopy Hood

When purchasing a canopy hood for your laboratory, several key features should be taken into account to ensure the system provides maximum efficiency and safety. Beyond confirming the installation method, there are a few more things to consider including the following:

- Size and Coverage Area: The size of the canopy hood should correspond to the dimensions of the equipment being used. A larger hood is necessary for larger equipment or operations that produce more fumes, whereas smaller hoods may be suitable for compact devices. The hood should have a sufficient coverage area to capture contaminants effectively.

- Baffling: Depending on the application, baffling may be needed to control the flow of the ducted fumes or vapors. Not all circumstances require baffling, but they can help to direct air flow properly as needed.

- Exhaust Ductwork: It is important to check the compatibility of the canopy hood with the laboratory's existing ductwork and ventilation system. The duct size and flow capacity must match the exhaust requirements of the hood to ensure proper ventilation.

- Corrosion Resistance: For laboratories that deal with corrosive chemicals or harsh conditions, the materials of the canopy hood must be resistant to corrosion. Stainless steel, polypropylene, and other corrosion-resistant materials are commonly used for this purpose.

- Ease of Maintenance: Canopy hoods should be easy to clean and maintain. Models with removable parts or smooth surfaces are easier to clean, reducing the buildup of hazardous materials inside the hood.

Where to Buy Canopy Hoods

M2 Sci offers a selection of premium quality canopy hoods in both wall and ceiling mountable configurations. Inter Dyne Systems stainless steel canopy hoods are manufactured right here in the US, and are made from high-quality type 304 stainless steel in a variety of sizes.